Choosing the right level sensor is essential for accurate tank monitoring, reliable process control, and reduced maintenance. Two of the most commonly used non-contact level measurement technologies are ultrasonic level sensors and radar level sensors.

If you’re selecting a tank level sensor for water, wastewater, or chemical storage, understanding how these technologies differ will help you make the right decision.

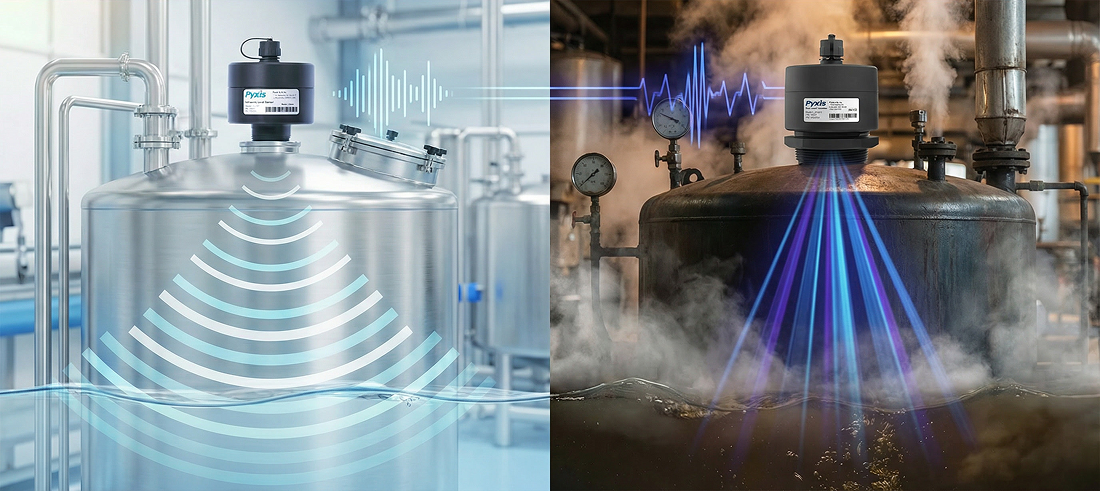

Ultrasonic Level Sensors – Best for Simple Tank Applications

Ultrasonic level sensors measure liquid level by emitting sound waves toward the surface and timing the reflected signal. They are commonly used in clean, non-pressurised tanks where conditions are stable.

Ultrasonic level sensors are ideal for:

- Clean water tanks and chemical storage

- Short measurement ranges

- Cost-effective level monitoring

Limitations to consider:

- Vapour, condensation, foam, or turbulence can affect readings

- Shorter measuring range compared to radar

- Small dead zone near the sensor

The Pyxis LS-200 Ultrasonic Level Sensor provides reliable non-contact liquid level measurement up to 2.7 metres. It includes 4–20 mA and RS-485 outputs, Bluetooth configuration, and an IP67 enclosure for industrial environments.

Radar Level Sensors – Reliable in Harsh Environments

Radar level sensors use microwave signals to measure level and are far less affected by process conditions. This makes them the preferred choice for demanding and critical applications.

Radar level sensors are best suited for:

- Tall tanks and long measurement ranges

- Wastewater and chemical process tanks

- Applications with vapour, steam, foam, or dust

Key advantages of radar level measurement:

- High accuracy and repeatability

- Stable performance in harsh environments

- Suitable for critical dosing and control systems

The Pyxis LSR-801 Radar Level Sensor uses FMCW radar technology to measure levels up to 15 metres, delivering consistent results for industrial tank level measurement.

Ultrasonic vs Radar Level Sensors – How to Choose

When comparing ultrasonic vs radar level sensors, the right choice depends on tank size, environment, and performance requirements.

-

Choose an ultrasonic level sensor for clean liquids, short ranges, and cost-sensitive installations

-

Choose a radar level sensor for high accuracy, long range, and harsh process conditions

For critical applications where reliability matters most, radar is typically the better long-term solution.

Need Help Selecting a Level Sensor?

If you’re unsure which level sensor is right for your application, CWC can help. Our team supports water, wastewater, and industrial sites with proven level measurement solutions.

👉 Start with these products:

Technical Director at Convergent Water Control, brings nearly 30 years of experience in the electronics industry spanning product design, prototyping, production, and technical support. With deep expertise in industrial automation, instrumentation, and chemical dosing systems, he excels in product management, business planning, and technical operations. Larry’s strong engineering background and leadership ensure the development of compliant, high-quality products and the delivery of exceptional technical support across every stage of a product’s lifecycle.