What Are Argal Vertical Sump Pumps?

Vertical sump pumps are intended for use in the industrial pumping applications to pump clean or lightly contaminated liquids, fibrous slurries and liquids containing large solids from sumps. The pumping head is suspended into the pumped liquids and the drive motor is dry installed on the top.

Vertical inline centrifugal pumps, as their name implies, are single stage centrifugal pumps that are specifically designed for vertical installation. Their suction and delivery are inline to provide a smooth flow of liquid through the system.

A vertical sump pump is made only for sump pump usage. The motor is mounted above the pump, on top of a vertical shaft. The impeller is in the bottom of the pump, and pumps product through a volute casing and up the discharge pipe.

Technical Data

-

Process sump pumps for aggressive liquids.

-

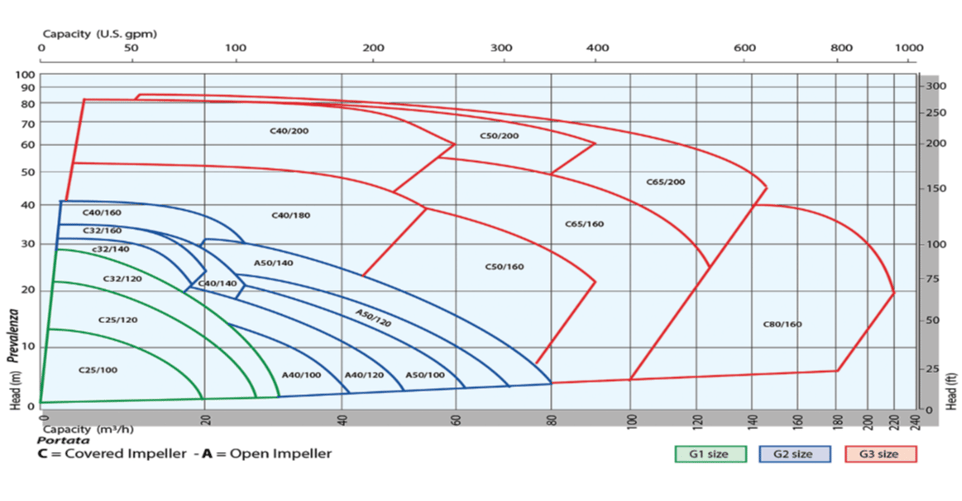

3 versions according to the performance and pump size: KGK G1 - G2 (radial volute

casing) KGK G3 (axial volute casing).

-

Available in materials PP or PVDF with column reinforced with fibreglass. (FRP).

-

Up to 275m3/h.

-

Column lengths from 0,5 to 5m.

-

3 motor execution available according to the specific gravity of the liquid pumped: "N" standard - 1,1 s. gravity ; "P" powered - 1,35 s. gravity ; "S" super-powered - 1,8 s. gravity.

-

Different flushing available.

-

ISO 9906:2012 Grade 2 conformity.

-

The shaft's guide bushings are made of ceramics or silicon carbide.

-

Different vapour sealing systems or rotating mechanical seals available for the protection against corrosion of the superior metallic parts.

-

No need for a sealing system against leaking.

-

The construction of the bushing and coupling is compact, ensuring an easier installation and improved use.

KGK | ARGAL

Advantages:

Polypropylene: Chemically and mechanically resistant, the thermoplastic polymer is used for KGK pump to transfer acids, alkalis, detergents or even solvents. Thanks to its properties and dimensional stability, polypropylene is wear-resistant, corrosion-resistant as well as moderately abrasion-resistant.

PVDF: Abrasive-resistance and highly stable fluoropolymers. Its chemical resistance allows pumps of highly abrasive liquids as well as corrosive and high-temperature fluids.

Fibreglass Reinforced Resin: The sump pump is made entirely of vinyl ester reinforced with fibreglass for offering a high-quality solution. The high resistance to corrosion and unique robustness allows operations in ambient temperature from -35°C to +40°C with no issues of expansion, retraction, or reduced mechanical strength. The column length reaches up to 5m.

Typical Applications

-

Aquarium, zoos, aquatic parks

-

Aquaculture

-

Desalination

-

Seawater processes

-

Chemical processes

-

Power plant

-

Metal treatments

-

Oil & gas

-

Pharmaceutical

-

Mineral industry

-

Water and wastewater treatments

For more information visit the full Argal range, contact us today!

Queensland BDM for Convergent Water Controls. Experienced in all facets of chemical metering and chemical transfer applications.